LM Packaging

LM Packaging

Cold Chain Labels

Get a Quote

Contact UsOverview

1. Product Overview

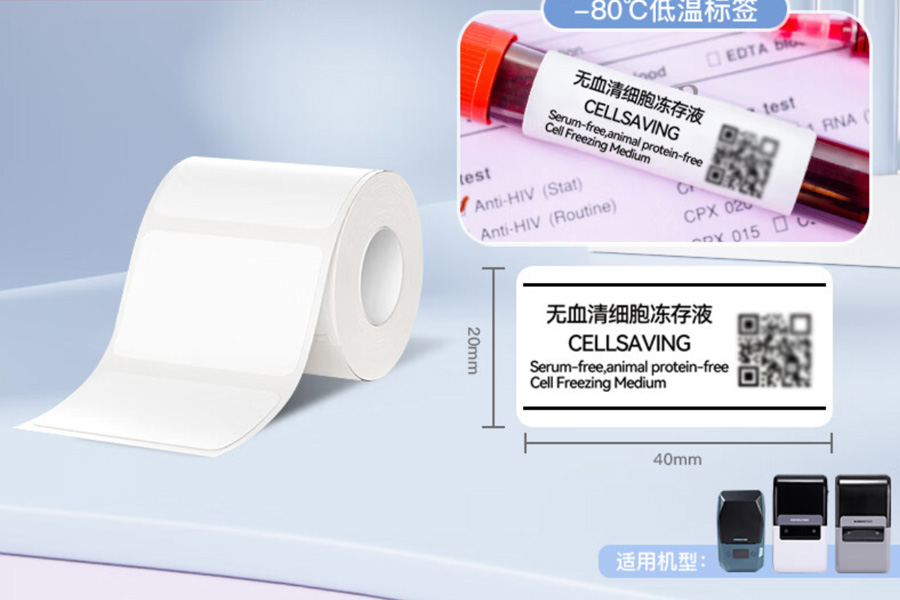

Cold Chain Labels are high-performance labels specifically designed for the medical and pharmaceutical industry. These labels are ideal for identifying and tracking temperature-sensitive products (such as vaccines, biologics, and pharmaceutical items) during cold chain transportation. Made with high-sensitivity thermal materials and low-temperature adhesive technology, Cold Chain Labels maintain clear print quality and strong adhesion even in extreme cold conditions, such as refrigerated or frozen environments. They meet stringent regulatory requirements while ensuring the integrity and accuracy of critical information throughout transportation.

2. Product Specifications & Applications

We provide a variety of Cold Chain Label sizes to accommodate different packaging and logistics needs:

50mm x 30mm: Suitable for small pharmaceutical containers, such as individual vaccine vials, test tubes, and small biologic containers.

70mm x 50mm: Ideal for medium-sized packaging, such as medicine boxes and biologic kits.

100mm x 80mm: Designed for large cold chain shipping containers or palletized packaging, such as bulk pharmaceutical shipping boxes and logistics pallets.

Key Applications:

Vaccine Transportation: Labeling vaccine batches, production dates, and temperature control requirements to ensure traceability.

Biological Product Logistics: Providing clear identification for blood products, antibody medications, and refrigerated reagents.

Pharmaceutical Cold Chain Management: Marking critical tracking information, such as batch numbers, storage requirements, and transport conditions, for bulk medicine shipments.

Medical Equipment Transportation: Labeling cold chain medical devices and diagnostic reagents for shipment.

3. Product Features

Exceptional Low-Temperature Performance: Maintains strong adhesion and stability in environments as cold as-25°C, ensuring labels do not peel or curl in extreme conditions.

High-Definition Printing: Premium thermal materials produce sharp, durable prints that remain legible over time.

Waterproof and Moisture-Resistant: Designed to withstand humid conditions and condensation commonly encountered in cold chain logistics.

Scratch-Resistant Durability: The surface is resistant to abrasion, keeping information intact even during transportation.

4. Our Product Advantages

Custom Solutions: Offers tailored label designs, including specific sizes, shapes, and functionalities, to meet the unique needs of the medical and pharmaceutical sector.

High-Quality Assurance: Manufactured with cutting-edge equipment and strict quality control processes to ensure consistent performance across all products.

Fast Turnaround and Delivery: Robust production capabilities and a global logistics network support urgent order requirements.

Cost Optimization: Direct factory production and supply reduce procurement costs for clients.

Comprehensive Technical Support: Provides end-to-end services, including product selection and usage guidance, ensuring a seamless customer experience.

5. Industry Pain Points & Solutions

Industry Pain Points:

Adhesion Issues in Low Temperatures: Standard labels often fail to adhere in refrigerated or frozen environments, leading to missing or unclear information.

Moisture and Condensation Problems: Humidity and condensation during cold chain logistics can cause traditional labels to fail or lose legibility.

Transportation Abrasion: Labels frequently experience friction or scratches during transit, causing damage or loss of information.

Strict Regulatory Compliance: The medical and pharmaceutical industry demands high-quality, traceable labels, which standard solutions often cannot meet.

Our Solutions:

Specialized low-temperature adhesive formulas ensure labels stay firmly attached in extreme cold.

Waterproof and moisture-resistant designs protect labels from humidity and condensation, maintaining information integrity.

Scratch-resistant and durable surfaces withstand the challenges of long-distance transportation.

Labels are designed to meet international medical and pharmaceutical standards, helping clients comply with regulations.