Common Label Materials in the Cosmetics Industry | ||||

Label Material | Description | Suitable Substrates | Common Printing Techniques | Typical Applications |

Clear BOPP (PP) | High transparency, flexible, waterproof, oil-resistant, "no-label" look | Glass bottles, PET bottles, acrylic bottles | UV printing, screen printing, flexo, hot stamping | Serums, mists, perfumes |

White BOPP (PP) | Opaque white base, good adhesion, cost-effective | Plastic bottles, tubes | Flexo, UV printing, hot stamping, cold foil | Cleansers, lotions, facial masks |

Pearlescent Film | Glossy, pearl finish, soft texture, premium appearance | Plastic bottles, soft tubes | Flexo, hot stamping, spot varnish | Facial cleansers, BB creams, skincare sets |

PET (Clear/White) | Strong, heat-resistant, excellent clarity (clear version) | Glass, plastic, and metal containers | UV printing, screen printing, hot stamping | Perfumes, eye creams, ampoules |

PVC (Clear/White) | Flexible, moderate clarity, not environmentally friendly | Glass and plastic bottles | Screen printing, UV printing | Mass-market personal care |

Synthetic Paper (PP-based) | Waterproof, oil-resistant, matte finish, budget-friendly | Plastic bottles, shampoo bottles | Flexo, hot stamping, screen printing | Shampoos, body washes |

Coated Paper | Paper-based, non-waterproof, suitable for short-term use | Paper boxes, paper tubes | Offset, flexo, spot UV | Mask outer packaging, boxed sets |

Metallic Foil Paper | Strong metallic sheen, luxury appeal | Glass, gift boxes, rigid packaging | Offset, hot stamping, screen printing, embossing | High-end gift boxes, fragrance products |

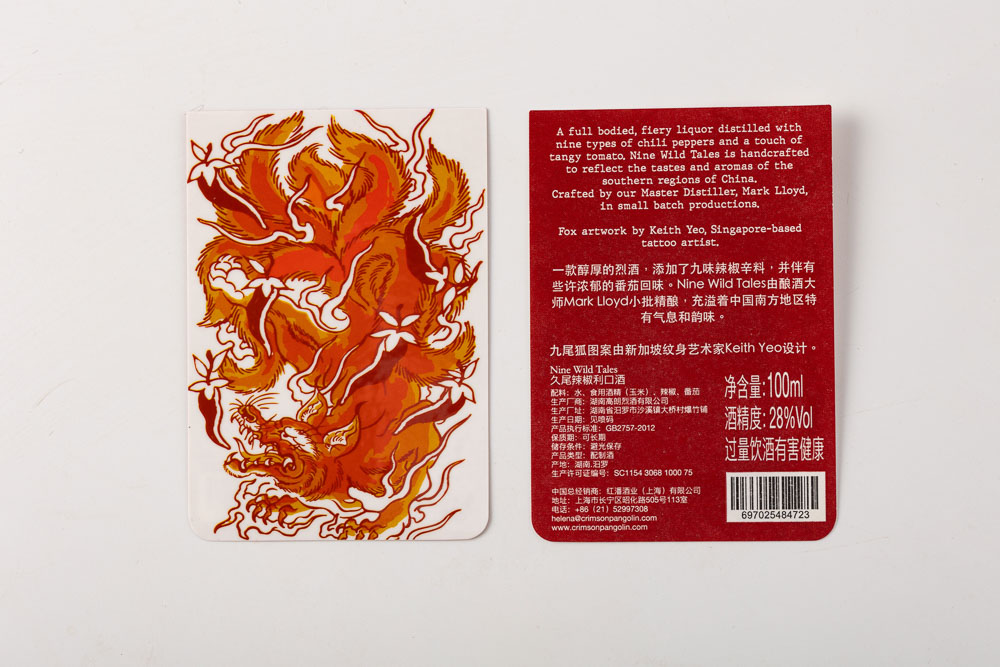

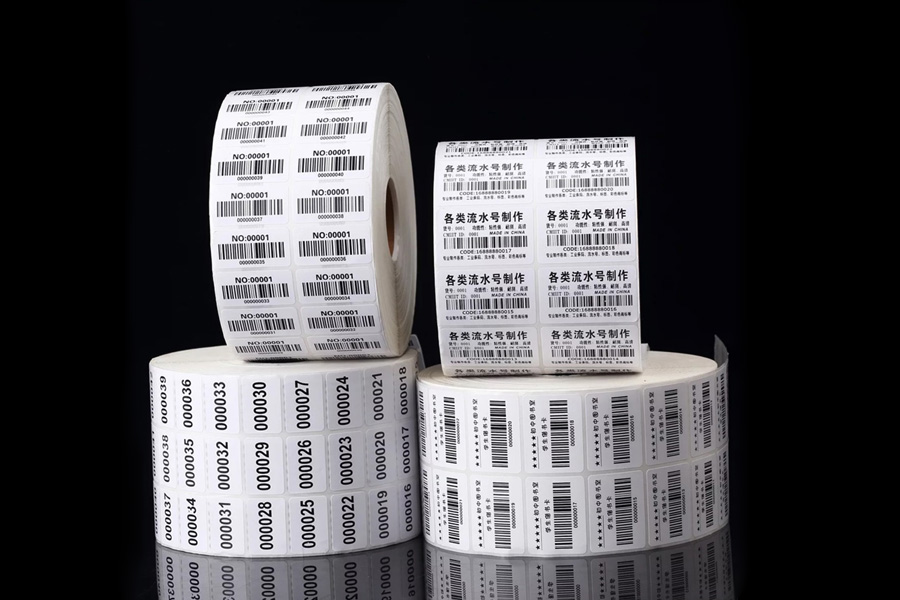

Security Label Materials | Supports variable data, anti-counterfeit elements (laser, scratch-off, QR) | Any surface | Laser engraving, variable inkjet, thermal transfer | Brand protection, traceability |

Label Material vs. Packaging Substrate Compatibility | ||

Packaging Substrate | Recommended Label Material | Reason/Benefits |

Glass bottles | Clear PET, Clear BOPP | High transparency, strong adhesion, premium no-label effect |

PET plastic bottles | White BOPP, Pearlescent Film | Good adhesion, cost-effective, scuff-resistant |

PE soft tubes | PE film, flexible synthetic paper | Flexible and conformable, resists edge-lifting and wrinkling |

Acrylic bottles | PET, BOPP, Metallic Foil Paper | High clarity, gloss, and luxury texture |

Aluminum/metal containers | PET, PVC, Metallic Foil Paper | Strong adhesion, durable, luxurious appearance |

Paper boxes | Coated paper, foil paper, textured paper | High-quality feel, suitable for premium packaging presentation |

Printing Techniques by Label Material | |||

Material | Recommended Printing Methods | Foil/UV Suitability | Remarks |

Clear BOPP | UV printing + white ink, screen, cold foil | ✅ Yes | Ideal for “no-label” appearance |

White BOPP | Flexo, UV printing, hot stamping | ✅ Yes | Good value and broad applicability |

PET | Screen, UV printing, hot stamping | ✅ Yes | Preferred for premium packaging |

PVC | UV, screen printing | ⚠ Partial | Less eco-friendly, may have odor |

Pearlescent Film | Flexo + hot stamping, spot varnish | ✅ Yes | Adds luxury texture, great for cosmetic sets |

Coated Paper | Offset, flexo, lamination | ⚠ Not waterproof | Requires lamination for protection |

Metallic Foil Paper | Offset + embossing/hot stamping | ✅ Yes | Strong metallic effect, ideal for luxury products |

Synthetic Paper | Flexo, UV, hot stamping | ✅ Yes | Used for mass-market skincare and bath products |