Common Label Materials in the Agrochemical Industry | |||

Label Material | Key Characteristics | Pain Point Addressed | Typical Applications |

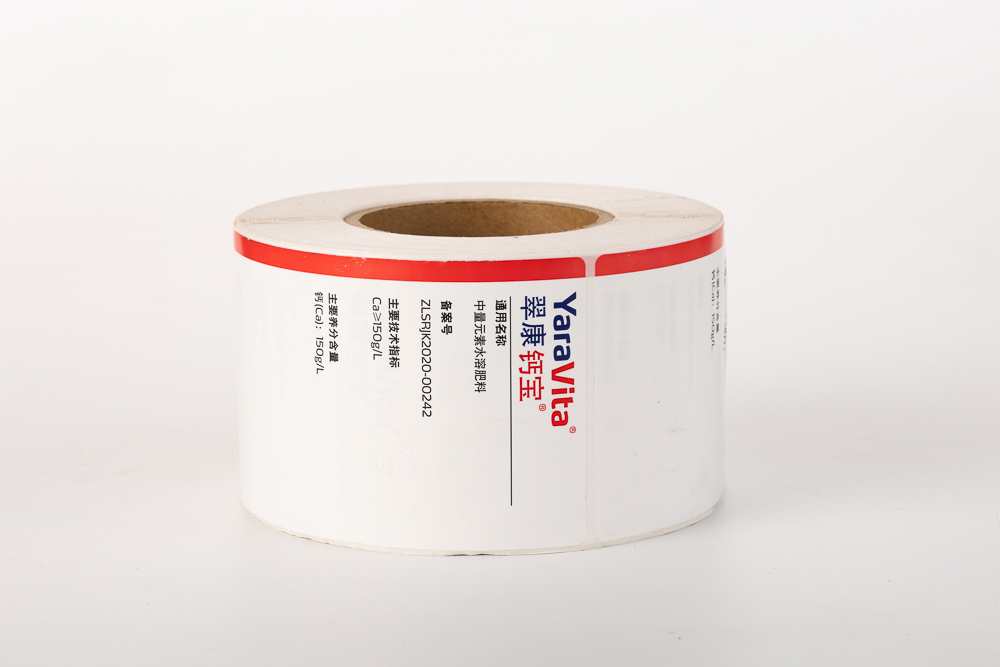

White PE (Polyethylene) | Soft, water-resistant, chemical-resistant, conforms to curved surfaces | Curved container adhesion, chemical exposure | Pesticide bottles, liquid fertilizer |

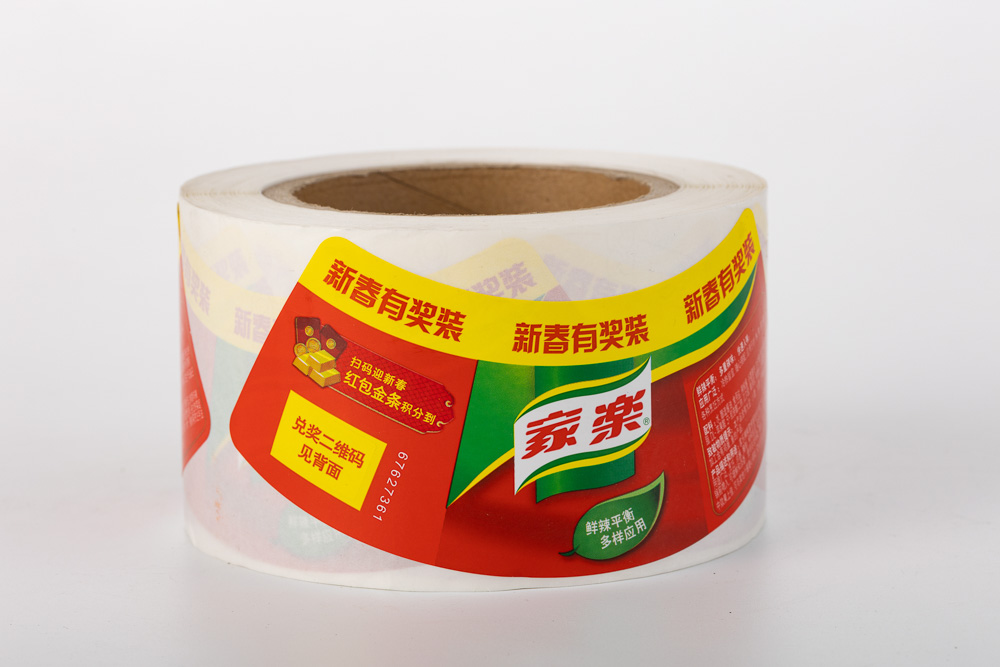

White BOPP (Polypropylene) | Rigid, print-friendly, moisture and solvent-resistant | Suitable for rigid containers | Herbicide cans, agro drums |

Transparent BOPP | High clarity, tear-resistant, chemical-proof | Premium branding, window effect | Branded agrochemicals |

PET (White/Clear) | High strength, heat-resistant, dimensionally stable | Large-volume containers, abrasion-resistant | Chemical drums, bulk packaging |

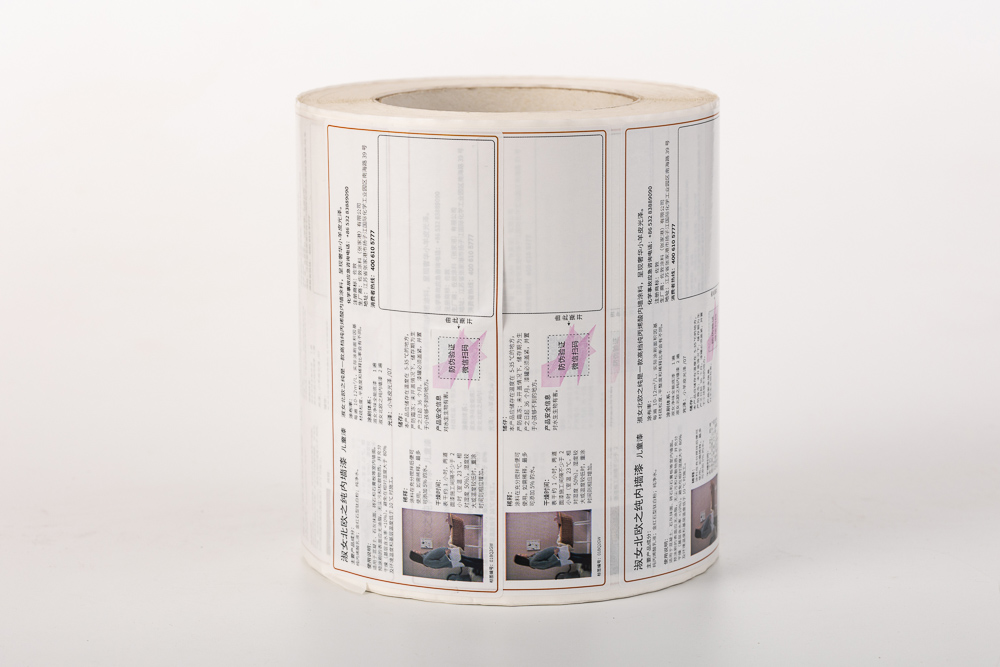

Synthetic Paper (PP) | Matte, waterproof, tear-resistant, economical | Cost-effective for mass production | Powder fertilizers, pouches |

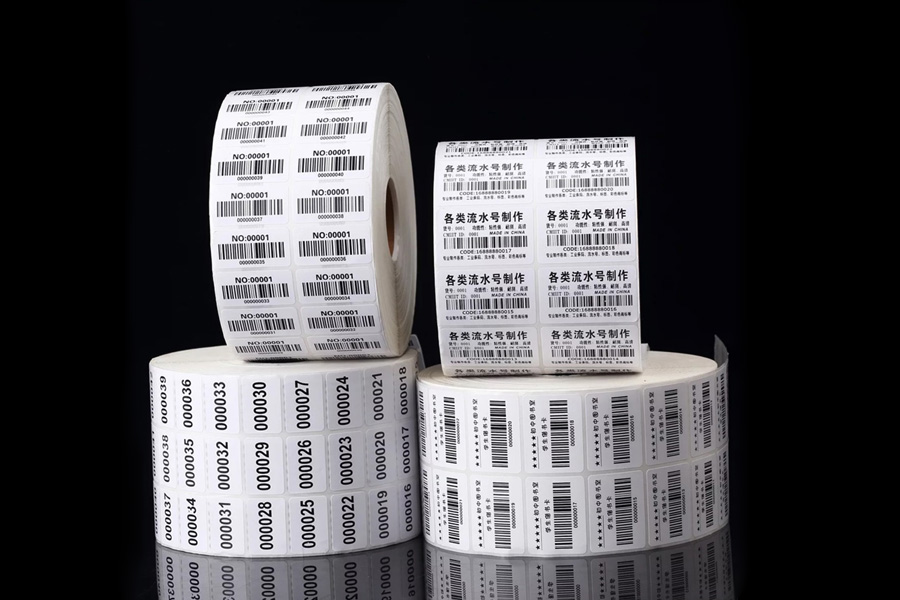

Direct Thermal Synthetic | Ribbonless printing, moisture/chemical-resistant | Variable data, logistics barcoding | Barcode, warehouse labels |

Aluminum Foil Composite | Excellent barrier, heat-resistant, tamper-evident | Cap seal, safety labels | Foil seals, warning labels |

Labeling Pain Points & Matching Solutions | ||

Pain Point | Recommended Solution | Suitable Material(s) |

Poor adhesion on curved bottles | Use flexible film with strong adhesive | White PE, Synthetic Paper |

Label damage from chemical exposure | Chemical-resistant face + protective coating | White BOPP, PET |

UV fading, weather-related degradation | UV-resistant ink + weatherproof film | BOPP, PET, Synthetic Paper |

Batch tracking / QR code requirements | Use thermal or transfer printable material | Direct Thermal, Synthetic Paper |

Label abrasion during handling/logistics | Use abrasion-resistant durable face stock | PET, BOPP |

Heat deformation or edge lifting | Use dimensionally stable films | PET, Aluminum Foil Composite |

Tamper evidence or seal requirements | Use foil sealing films, VOID films | Aluminum Foil, Tamper Film |

Packaging Substrate vs. Label Material Suitability | ||

Packaging Substrate | Recommended Label Material(s) | Reason/Benefit |

Curved HDPE bottles | White PE, Synthetic Paper | Flexible adhesion, chemical resistance |

Rigid PP / PET bottles | White BOPP, PET | High surface energy, long-term durability |

Plastic jerry cans | White BOPP, Synthetic Paper | Chemical and oil resistance |

Large drums (metal/plastic) | PET, BOPP, Aluminum Foil Composite | Durability in transport, weather-resistance |

Flexible pouches | Synthetic Paper, BOPP | Tear-proof, moisture-resistant, compatible with sealing |

Cap closures / foil seals | Aluminum Foil Composite, PET | Tamper-proof, heat-sealable |

Cartons / Shipping labels | Thermal Synthetic Paper | Suitable for batch/barcode tracking |