01 The Story Behind "Safe and Stable Supply" During the Pandemic

001 Production Couldn't Stop, No Matter WhatIn the first half of 2022, the epidemic situation in Shanghai became increasingly severe. Lingmin's production manager, seeing the rising numbers, felt uneasy. After observing with deep concern for a while, he decisively suggested to the company that key production line personnel should immediately be assigned to work on-site. On a chilly, rainy evening in March, an urgent notice was issued, urging all production line personnel to pack their spare clothes and blankets and rush to the company at 10 p.m. to begin their stay. Later, when interviewing the production manager at the Shanghai factory, I asked him why he made such a decisive decision. He said, "I didn't think much of anything at the time. I just thought, 'We still have a lot of unfulfilled orders, and we need to keep production running, no matter what.'" Touchingly, upon receiving the notice, the personnel on each production line immediately packed up and headed to their respective production stations. No one was late, and all relevant positions were in place and on time.

Everyone stayed there for 70 days, switching from long-sleeved shirts to short-sleeved shirts, using pallets and cardboard as mattresses, and sharing a single hot water tap for showers. They took turns showering daily. Even in such challenging conditions, none of the employees complained or regretted anything. We don't know how long this immobility will last. Despite our shared worries, anxieties, and concerns for our families, Lingmin employees persevered in their work, united in purpose and overcoming the challenges. This is how Lingmin's production remained operational during the pandemic.

002 Accurate Judgment, Strategic Stocking, and Unimpeded Supply

Maintaining uninterrupted production requires the coordinated efforts of all links and the seamless cooperation of every component. Procurement is a crucial backup force. The supply chain's ability to withstand pressure was one of the most challenging aspects during the pandemic.

The head of the supply chain department said in an interview, "The biggest challenge was logistics. We exhausted all our resources to find vehicles, starting with finding return vehicles for the epidemic prevention supplies. We also transferred supplies from Shanghai to Hangzhou, Nanjing, Jiaxing, Hefei, Pinghu, and other locations, switching trucks, drivers, and vehicles at highway service areas along the way. Thanks to our dedication, we successfully resolved the logistics challenges."

Although freight costs tripled or even quintupled during this period, we felt it was well worth it to meet all of our customers' production needs.

With nearly two decades of experience in the industry, Lingmin has accumulated extensive upstream and downstream resources, a professional and diverse supply channel system, and the ability to quickly mobilize resources. Coupled with the company's cautious management philosophy, the company's leaders reserved sufficient cash flow and stockpiled sufficient production materials, ensuring ammunition for the upcoming battle.

003 Overcoming All Difficulties to Address Customer Needs

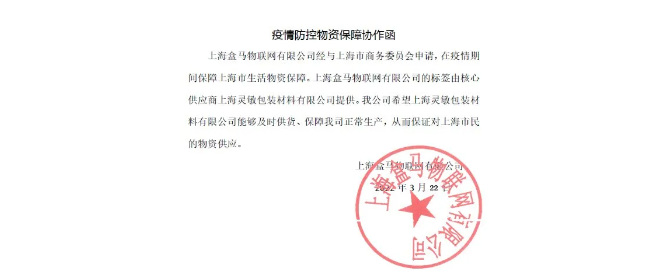

During the pandemic, the business department engaged in non-stop phone and video conference calls from morning till night. In addition to overcoming difficulties to arrange logistics and deliveries for customers, communicating and resolving technical issues, remotely monitoring production, and diligently serving existing customers, they also offered their full support to the many "emergency" businesses referred during the pandemic. Sharing challenges, as true friendship emerges in times of adversity, Lingmin has made many new friends during this period. Lingmin focused on both production and epidemic prevention efforts, ensuring continuous operations and undelayed fulfillment of customer orders. We were particularly honored to collaborate with Hema, a key customer for livelihood security, to ensure the supply of essential goods during the pandemic.

In recognition of Lingmin's tenacious performance during the pandemic, it was selected as one of the first companies to resume work on April 28th. Our partners expressed their gratitude and recognition for Lingmin's unwavering commitment to overcoming all challenges and maintaining continuous production, which made all the challenges worthwhile.

"Where collective effort is exerted, nothing can stop it; where collective wisdom is applied, nothing can fail." This is precisely why Lingmin has been able to navigate the currents of two pandemics in three years. Lingmin also maintains a tradition of continuous learning and keeping pace with the times.

02 Upholding this tradition of learning, Lingmin Lecture Hall Internal Training Begins

Every era has its own challenges, and every generation has its own mission. In this uncertain Vuca era, facing unexpected crises, we remain focused on our goals, remain calm, and persevere with an unyielding spirit. At the same time, we maintain our tradition of periodic internal training, deepening our inner strength and holding ourselves to high standards. We firmly believe that only by continuous learning and progress can we navigate the currents and calmly face the test of time. In the fourth quarter of 2022, we were fortunate to have industry leaders Wang Bin and Liu Fengyuan deliver professional lectures at the Lingmin Lecture Hall, focusing on human resources and market systems, respectively. Lingmin also invites interested upstream and downstream partners to participate in learning, discussion, and exchange.