Case Background

● Application Scenario: This high-temperature label is primarily used in the food industry, such as for hot drink cups at KFC. It is designed to withstand microwave heating while maintaining the clarity and integrity of product information. This label is ideal for food packaging that requires high-temperature processing, such as microwave heating and hot beverage containers.

● Technical Features: The label material is specially engineered to endure up to 80°C for 8 continuous hours, with added resistance to water, oil, and abrasion, ensuring reliable performance in high-temperature and humid environments.

Pain Points

1. Label Damage During Heating: Conventional labels tend to peel off, curl, or become illegible during heating, negatively impacting brand image and customer experience.

2. Food Safety Concerns: Labels for food packaging must meet food-grade safety standards and remain safe under high-temperature conditions without releasing harmful substances.

3. Difficult Information Identification: Labels in high-temperature, humid environments are prone to smudging or degradation due to oil or moisture exposure.

4. Aesthetic Challenges: Labels must maintain high-quality print designs to clearly display brand information without compromising packaging aesthetics.

Solutions

1. Heat Resistance

a. The label material withstands microwave heating, remaining intact and clear for up to 8 hours at 80°C.

b. Specifically designed for hot drink cups and microwaveable food packaging.

2. Food-Grade Safety

a. Made from materials compliant with food safety certifications, ensuring no harmful substances are released during heating.

b. Resistant to water and oil, maintaining label integrity throughout the food's lifecycle.

3. Clear Information Display

a. Supports high-definition printing for clear display of brand logos, ingredients, heating instructions, and other product information.

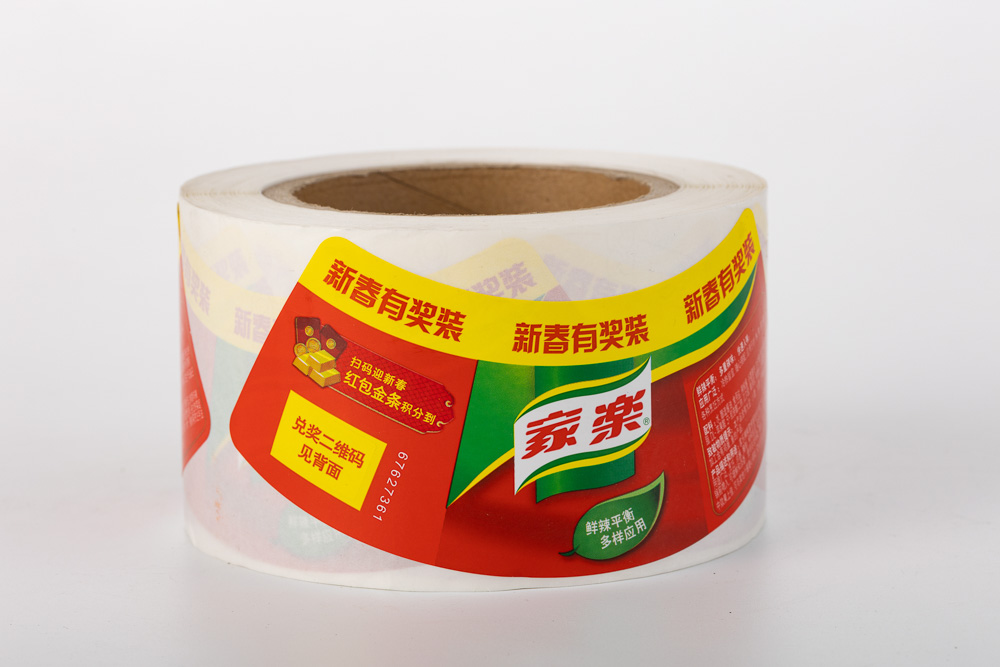

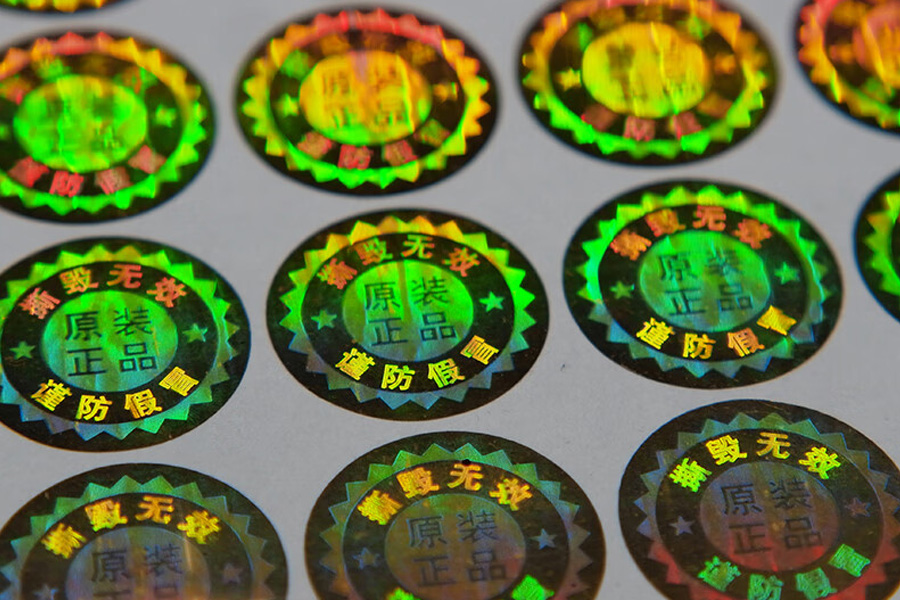

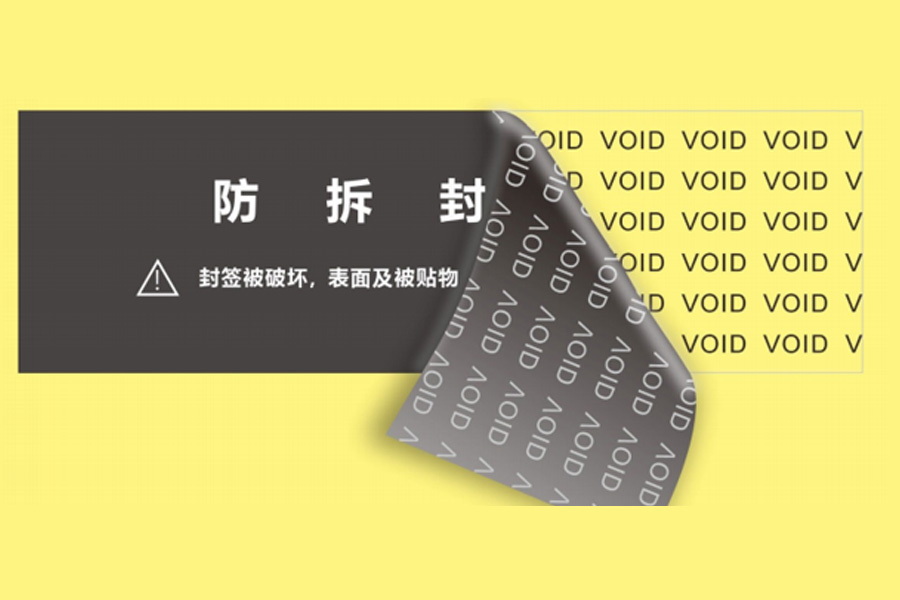

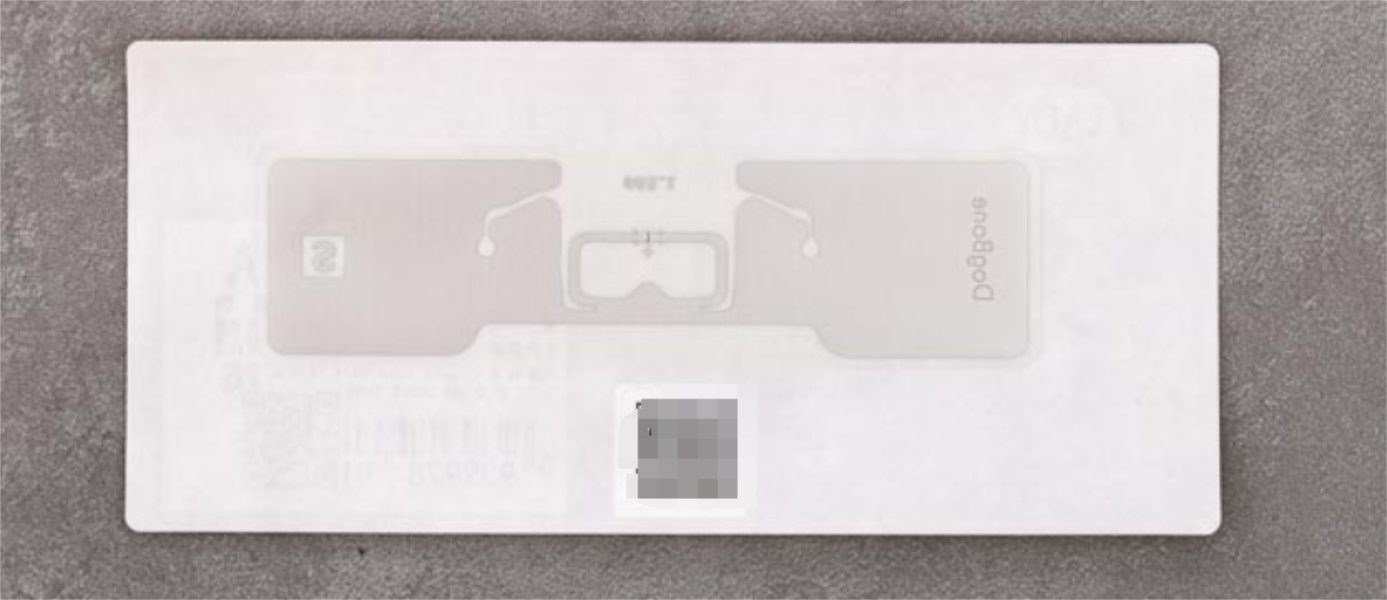

b. Integrates QR codes or anti-counterfeiting codes, allowing consumers to access additional product details or participate in promotional activities.

4. Strong Adhesion and Durability

a. Special adhesive formulas ensure firm attachment to paper, plastic, or glass surfaces, even in high-temperature and high-humidity conditions.

b. Surface features scratch and abrasion resistance, suitable for handling during refrigeration, transportation, and reheating.

Technical Features

1. Materials and Processes

a. Heat-Resistant Materials: Uses polyester (PET) or other high-temperature substrates, meeting the needs of microwave heating and high-temperature environments.

b. Protective Coating: Coated with water- and oil-resistant layers while ensuring food safety compliance.

2. Integrated Functionality

a. Supports unique identification codes such as QR codes, barcodes, or anti-counterfeiting codes for product traceability and marketing.

b. Surface-resistant to scratches and UV light, extending the label's lifespan.

3. Eco-Friendly and Aesthetic Appeal

a. Made from recyclable or eco-friendly materials, meeting green packaging requirements for the food industry.

b. High-quality printing delivers vibrant colors and intricate designs, enhancing brand image.

Applicable Industries

● Food Industry: Hot drink packaging labels (e.g., coffee, milk tea, hot chocolate cup stickers).

○ Microwaveable food packaging (e.g., ready-to-heat meal boxes).

○ High-temperature sterilized food packaging (e.g., canned food, instant meals).

● Other Related Industries: Restaurant takeout, airline meal boxes, convenience store ready-to-eat products.

Customization Services

● Size and Shape: Labels can be tailored to specific sizes and shapes to fit different food packaging designs.

● Materials and Features: Various heat-resistant materials are available, with options to integrate QR codes and anti-counterfeiting technologies.

● Printing and Safety: High-definition printing supports branding, heating instructions, and other information, ensuring food safety compliance.