Case Background

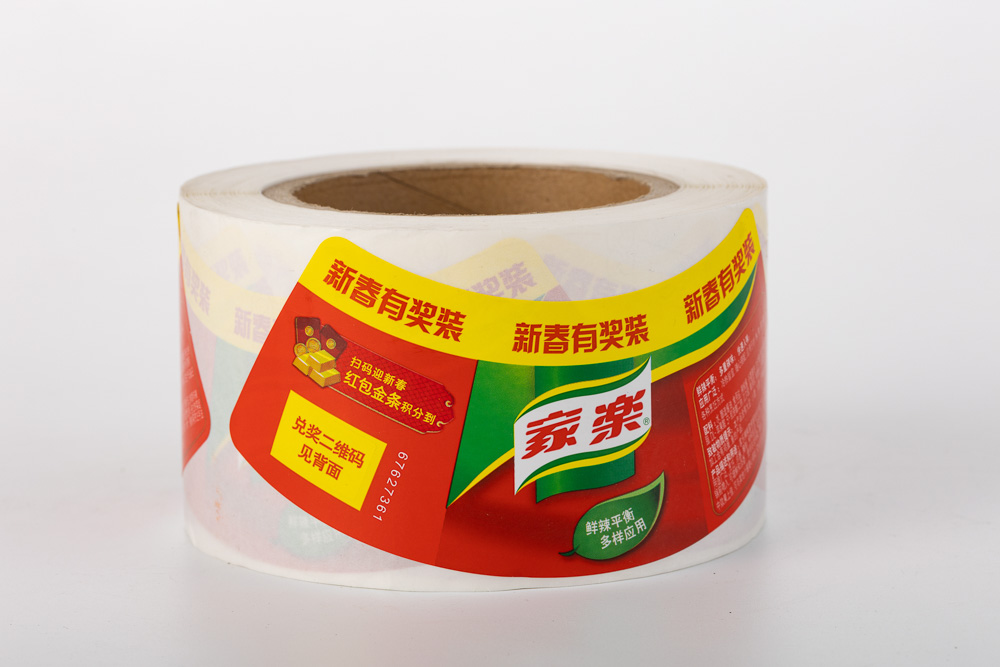

● Application Scenario: In-mold labels (IML) are labels embedded within packaging materials, widely used in industries such as food and beverage, personal care, pharmaceuticals, home appliances, and automotive components for plastic containers or packaging products.

● Technical Features: Labels are molded into the packaging during production, becoming an inseparable part of the container. This enhances product aesthetics while providing anti-counterfeiting, waterproofing, and abrasion resistance.

Pain Points

1. Traditional Labels Peel Off Easily: Conventional labels on the surface are prone to moisture, scratches, or detachment, compromising appearance and information integrity.

2. Aesthetic Limitations: Standard labels fail to seamlessly blend with the packaging, hindering brand image enhancement.

3. Challenges in Anti-Counterfeiting and Traceability: Ineffective at preventing tampering or imitation, lacking reliable anti-counterfeiting and traceability features.

4. Environmental Concerns: Growing demand for sustainable and eco-friendly packaging solutions.

Solutions

1. High Adhesion and Durability

a. Labels are bonded to plastic containers through one-step injection molding, ensuring strong adhesion and preventing detachment or damage.

b. Resistant to high temperatures, humidity, and abrasion, suitable for cold storage and transportation.

2. Enhanced Brand Image

a. Labels are embedded within the container, creating a smooth, premium appearance.

b. Supports high-definition graphic printing, delivering vibrant designs that boost brand recognition.

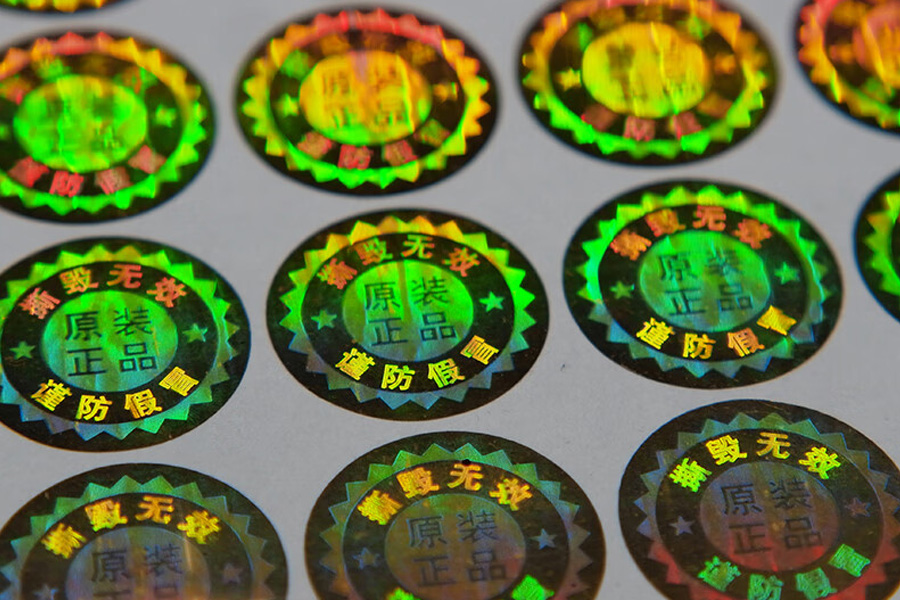

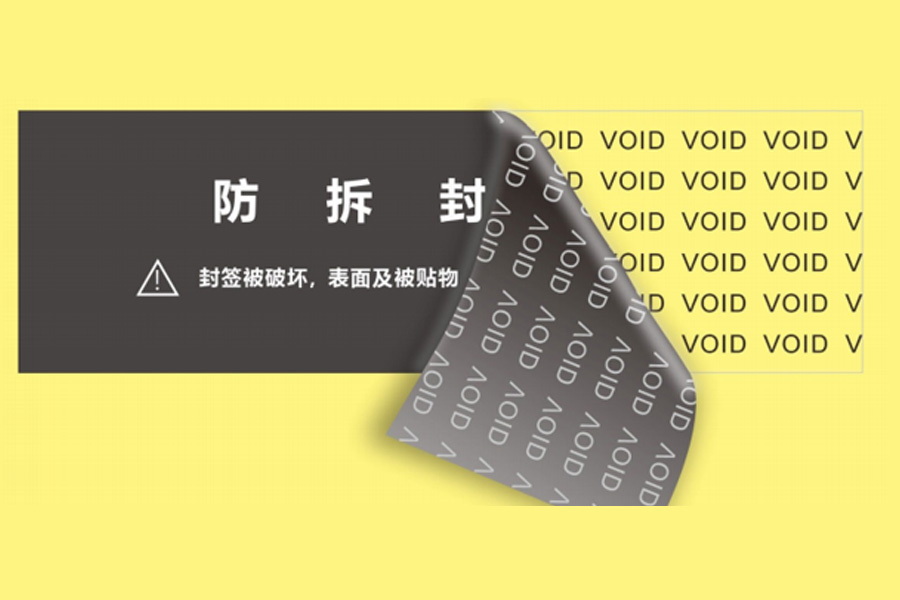

3. Anti-Counterfeiting and Traceability

a. Labels cannot be removed, preventing tampering or counterfeiting.

b. Can integrate QR codes or unique identifiers for anti-counterfeiting and full product lifecycle traceability.

4. Eco-Friendly and Sustainable

a. Labels are made from the same material as the container, facilitating recycling.

b. Options for biodegradable materials are available to meet green packaging requirements.

Technical Features

1. Label Molding Process

a. IML (In-Mold Labeling): Labels are integrated with plastic containers during injection molding, blow molding, or thermoforming.

b. Material Compatibility: Compatible with PP, PE, and other plastic materials for diverse packaging needs.

2. High-Quality Printing

a. Supports high-definition UV printing, offering vibrant colors and intricate designs.

b. Surface effects can include matte, glossy, or metallic finishes as required.

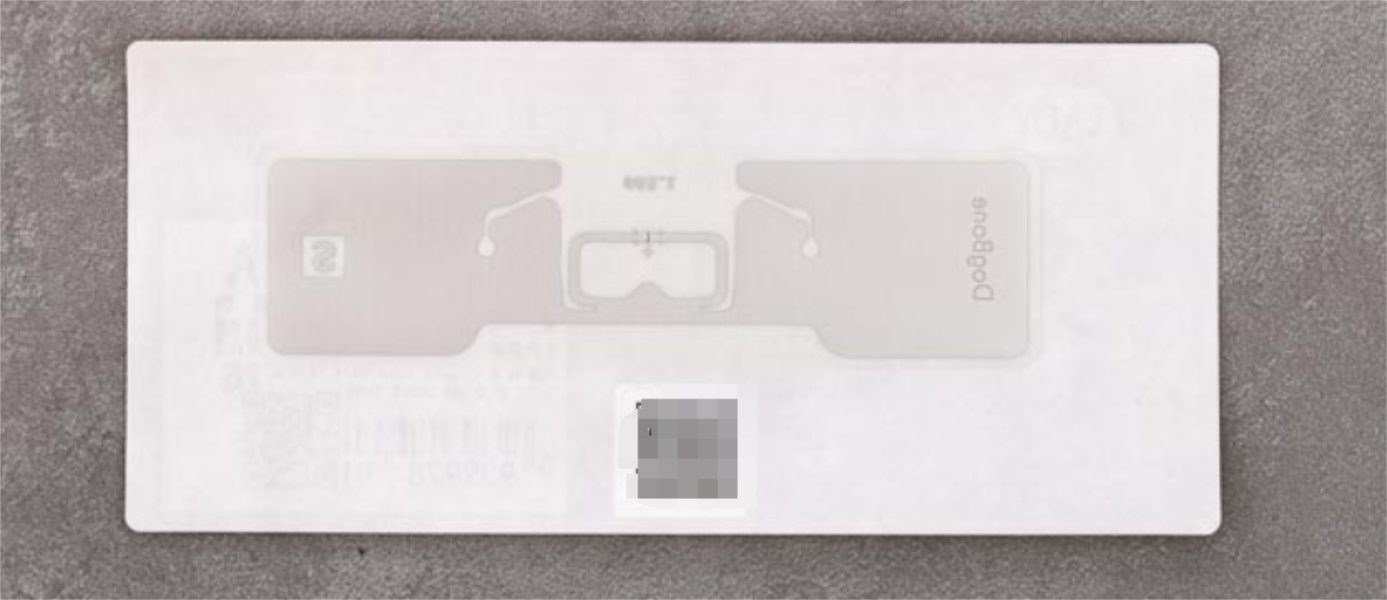

3. Functional Integration

a. Can embed QR codes, invisible codes, or other smart identification technologies.

b. Labels can include anti-scratch or UV-resistant coatings to extend product lifespan.

Applicable Industries

● Food and Beverage: Plastic bottles or packaging for dairy products, juices, and carbonated drinks.

● Personal Care: Plastic containers for laundry detergent, hand soap, and shower gel.

● Pharmaceuticals: Labels for medicine packaging and bottles.

● Home Appliances and Automotive: Decorative panels for home appliances and labels for automotive components.

Customization Services

● Size and Shape: Labels can be tailored to specific packaging requirements.

● Materials and Processes: Various materials and anti-counterfeiting techniques, such as laser etching and scratch-resistant coatings, are available.

● Data and Functionality: Integration of QR codes, RFID, and other technologies for multifunctional, customized labels.