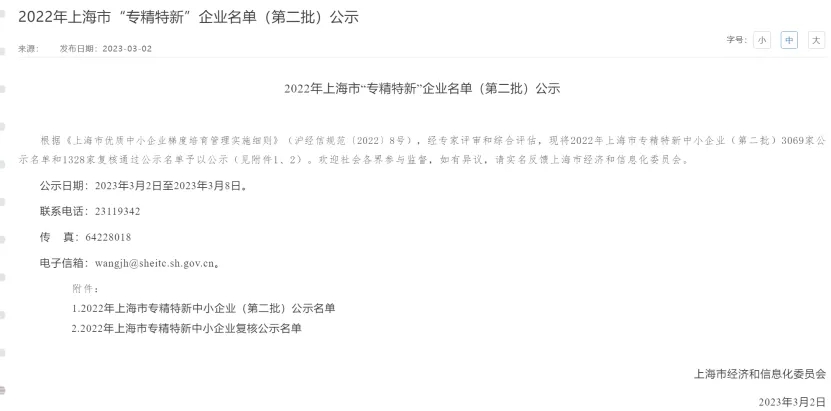

According to the "Implementation Rules for the Gradual Cultivation and Management of High-Quality Small and Medium-Sized Enterprises in Shanghai" (Shanghai Economic and Information Standards (2022) No. 8), and following expert review and comprehensive evaluation, Shanghai Lingmin Packaging Materials Co., Ltd. has officially been designated as one of Shanghai's "Specialization, Precision, and Innovation" enterprises after a public announcement period.

In 2003, Lingmin Packaging was founded as a small, unknown workshop primarily engaged in packaging and printing. Over the past 20 years, with steady progress and perseverance, we have continuously strengthened our technological foundation, established production lines, stabilized our supply chain, and improved our service system, striving to provide customers with superior service.

Every effort we make to meet customer needs is an opportunity to systematically optimize our R&D, testing, manufacturing, and supply chain. From an innovation perspective, the process of discovering and meeting needs is itself a process of knowledge creation between both parties. This new knowledge is the key to optimizing resource allocation and building advanced productivity. The key to becoming a "Specialization, Precision, and Innovation" enterprise lies not only in sustained growth but also in achieving continuous breakthroughs. As Xinhua News Agency's editorial on "Specialized, Advanced, and Innovative" enterprises stated: "Becoming a specialized, advanced, and innovative enterprise often involves setting a goal of excellence while benchmarking against top companies, undergoing transformation and refinement in meeting world-class demands, achieving a "lonely, brave" leap from a precipice, and becoming an innovative fulcrum in the global value creation network by pushing the boundaries of one's own capabilities."

Over the course of its 20-year journey, Lingmin has consistently adhered to the development philosophy of "Specialized, Advanced, and Innovative":

01 Build expertise through professionalism, deepen core business, and persevere in building a lasting business

Lingmin has been deeply involved in the packaging industry for two decades, accumulating strong capabilities, meticulous craftsmanship, and refined technology. The company holds numerous utility model patents, invention patents, software copyrights, and non-patented technologies. It has invested heavily in advanced domestic and international production equipment and has upgraded multiple high-performance production lines. Based on its one-to-one smart labeling system, supported by precision marketing and anti-counterfeiting and traceability systems, the company continuously breaks through technological barriers and leverages advanced digital packaging technology to drive the transformation and upgrading of the traditional packaging industry.On the one hand, it continuously accumulates experience and solidifies its foundation in the traditional packaging sector. While enhancing the technology used to serve traditional packaging companies, we also refine our technology, continuously advance with the times, break through technological barriers, and become a comprehensive provider of customized packaging solutions.

02 Lean efficiency, continuous improvement, and the spirit of craftsmanship.

001 Enhance the capabilities and stability of the processing process, and enhance the robustness of both processes and products.By implementing standardization and solidifying product processing parameters, we reduce repetitive work and errors for process developers, thereby improving efficiency. We promote standardization of each process, solidifying every aspect of production, and reducing anomalies and losses caused by uncertainty and arbitrariness.

002 Optimize the entire process, from ordering, production, logistics, to after-sales service, to improve efficiency and rapidly address customer needs.

We optimize the integration of pre-launch product introduction, box structure development, and application-specific design with new product prototyping and development processes to improve efficiency and shorten new product development and prototyping cycles. We are committed to improving efficiency, rapidly responding to customer needs, and enhancing customer satisfaction.

003 Shorten production cycle times and production setup time to accurately and quickly understand and respond to customer needs.

Through streamlined operations, thorough upfront communication on requirements, and extensive experience in application scenarios, we rapidly translate "what customers need" into "what we can do," enabling us to accurately and quickly understand and respond to customer needs.

004 Deepen refined management

Standardize the collection and use of printing materials, waste control, and unused quantities to reduce consumption and, consequently, printing costs.

Monitor production in real time to identify problems and promptly analyze and resolve them, minimizing process waste.

Strictly control raw material usage to improve utilization rates at every stage.

Improve facility layout, reduce production space, and effectively utilize resources.

Improve production staff skills to reduce plate changeover time and quality loss.

Promote the spirit of craftsmanship. Through skills training and competitions, we encourage everyone in every position to delve into technology. We also promote and share skills and best practices internally for mutual progress.

03 Win the market with distinctive features, stand out from the crowd, and deepen internal service capabilities.

As a service-oriented manufacturing industry, the packaging industry faces significant market competition variations due to the different packaging products and customer services it provides. Traditional packaging products face severe market homogeneity and fierce competition. However, the demand for customized packaging places higher demands on product design, material selection, production processes, safety production, and quality testing. Consequently, there are only a few qualified paper printing and packaging companies, resulting in insufficient market competition.Lingmin's comprehensive services encompassing product design, material selection, production processes, safety production, and quality testing have established its capabilities in providing comprehensive packaging solutions. This includes customized product design and material selection, along with technical expertise in various production processes, including letterpress, gravure, offset, screen, flexographic, and digital printing. Furthermore, Lingmin maintains a comprehensive ISO-certified quality control system, and is actively strengthening its warehousing and transportation capabilities to support just-in-time production methods.

This comprehensive solution capability has always been a key service focus for Lingmin.

04 Innovation for Development, Overcoming Weaknesses and Strengthening Strengths, Becoming the Core of Innovation

001 Development and Application of New Equipment and TechnologiesAs the saying goes, "To do one's work well, one must first sharpen his tools." Leading-edge processing technology and production equipment are fundamental to accelerating product research and development. Introducing new equipment and technologies, or actively researching equipment and technology innovation and transformation, to build competitive advantages in equipment and technology, optimize production line layouts, and address weaknesses and strengthen strengths are also part of the agile execution strategy.

High-end equipment with superior performance and energy conservation and environmental protection is gradually replacing poorly performing and energy-intensive production equipment. Advanced, multi-purpose, integrated packaging production equipment is gradually replacing outdated, single-function packaging equipment.

The widespread adoption of integrated automated production equipment and technologies has significantly shortened printing and packaging production cycles and improved production efficiency, thereby achieving the goal of maximizing profitability.

002 Restructuring the R&D System and Cultivating an Innovative Spirit

We are exploring and establishing a comprehensive scientific and technological innovation system within our service offerings. This system is driven by the market, employs advanced concepts, tools, and working methods, is staffed with a comprehensive team of responsible personnel, and maintains a rigorous organizational structure. Driven by both market forces and R&D, we continuously feed back and improve our mechanisms, creating a fertile ground for innovation.

Specialized, specialized, and innovative enterprises are the most agile link in the industry chain, inherently advantageous in their responsiveness and swift action. This advantage is achieved through our ability to connect resources within the industry chain and our dynamic organizational capabilities. Leveraging Lingmin's extensive knowledge and experience in precision manufacturing, Lingmin has developed a highly efficient, service-oriented manufacturing process. This allows Lingmin to conduct agile R&D and lean manufacturing for clients' small-batch products, enabling immediate response to market changes.

Lingmin Packaging has consistently adhered to the development philosophy of "specialization, precision, distinctiveness, and innovation," striving to keep pace with the times and achieve shared growth. Based on expertise, precision, distinctiveness, and innovation, Lingmin consistently upholds a "flexible and agile" approach.