Shanghai Lingmin Packaging offers one-stop professional paper packaging services with innovative concepts, using packaging to help companies reduce costs, increase efficiency, and achieve digital transformation. With over 20 years of industry expertise, we meticulously refine every detail of the complete packaging design process, focusing on customer needs. We are dedicated to reducing costs and increasing efficiency for brands.

Lingmin's expertise is reflected in the details of our services:

Packaging is the direct carrier of products to consumers. In today's brand communication process, its function is increasingly being expanded by brand marketing needs. Packaging design must not only be aesthetically pleasing but also ensure smooth operation during the production process.

This requires special attention to design optimization to improve production efficiency, reduce scrap, and maximize resource utilization.

When considering production use, we must fully consider the compatibility between packaging and equipment. For manual packaging, we must ensure ease of use and assembly, thereby improving production line personnel efficiency.

So, in what specific areas can Shanghai Lingmin Packaging help brands reduce costs and increase efficiency?

01 Optimizing Packaging Design

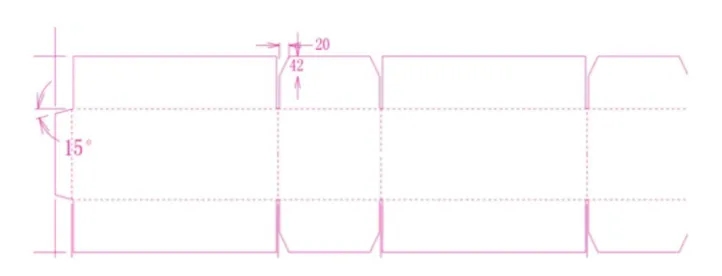

For example, when designing corrugated boxes for use on automated production lines, we often bend the corners of the flaps. This minor change not only maintains the product's protective function but also effectively prevents the flaps from colliding during folding, thus avoiding machine jams and product scrap.This design adjustment was designed to better meet production needs, ensuring a smoother production process and reducing potential issues. This is a prime example of packaging design taking production use into account.

For example, the integrated gift box structure breaks with traditional design, allowing the entire package to be formed in one go, reducing the number of production steps involved in packaging processing and molding. In particular, the integrated molding process no longer uses adhesives, relying instead on built-in snap-on closures. This not only reduces the use of adhesives, achieving sustainable packaging development, but also significantly reduces material waste and labor. More importantly, automated production improves production efficiency and shortens production cycles.

Furthermore, the integrated packaging structure, with its multiple sides fully connected, allows the package to unfold and flatten completely after opening, significantly reducing packaging volume. This significantly saves shipping space, enables large-scale shipments, and reduces shipping costs. Subsequent product molding facilitates operations, significantly improving the efficiency of manual boxing and loading processes in the factory. Optimizing packaging design helps brands reduce costs and increase efficiency.

02 Adjusting Packaging Methods

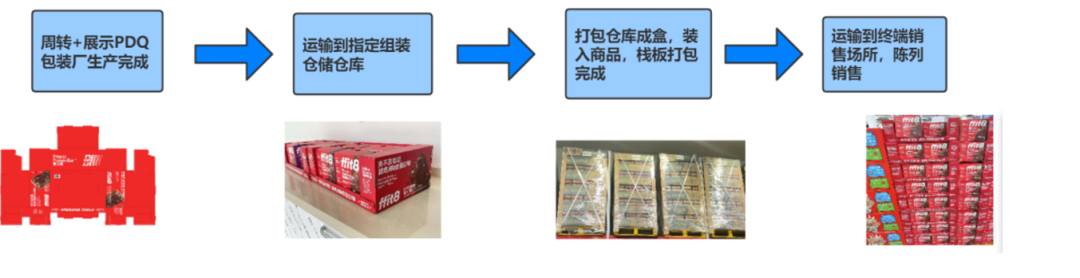

In addition to optimizing packaging structure to meet production needs, changing packaging methods can also improve production efficiency. The function of packaging is evolving with changing sales scenarios. For example, when products leave the factory, they require not only the packaging themselves but also a transfer box. After they arrive at the sales floor, they are unpacked and then put on the shelves by sales staff. Different packaging processes require different packaging, including product packaging, transfer box packaging, shelves, and point-of-sale (POS).Currently, many warehouse clubs like Hema and Sam's Club are eliminating the intermediate packaging step and using a direct PDQ+ pallet system for delivery to the sales floor. Stacked PDQ directly replaces shelves, integrating transfer, display, and exhibition functions. This reduces packaging steps, improves efficiency, saves costs, and facilitates display.

03 Adjusting Packaging Materials

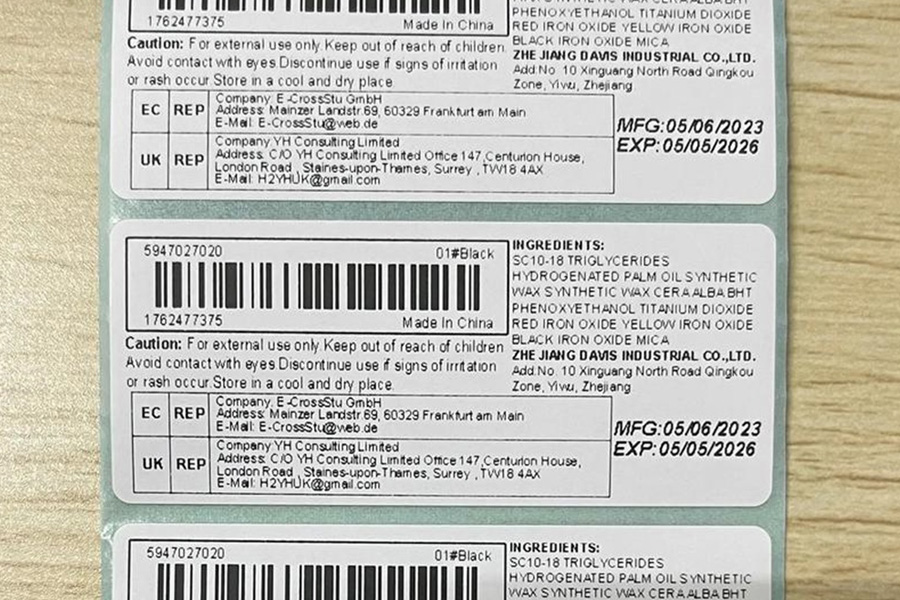

For example, when applying hot beverage labels, conventional label materials are subjected to temperatures of 80°C or higher, resulting in a 70% or higher probability of bubbles and label warping. The specific usage environment of hot beverages places high demands on the label's "adhesiveness" and the material's "high-temperature resistance." Lingmin conducted countless experiments to identify suitable materials. By combining specialized materials with advanced processing techniques, Lingmin ultimately resolved this pain point for the industry.

When optimizing packaging for improved efficiency, there are many approaches. From a production and usage perspective, even small changes can yield significant benefits. For example, reducing a step, changing a material, or optimizing a structure can significantly improve production.

Packaging cost reduction isn't just about cost; it also affects quality, brand, and consumer experience. Only by comprehensively considering all factors can we develop the most effective cost reduction strategy and create greater value for our clients.

Lingmin always considers the entire packaging lifecycle and its clients' performance challenges to identify effective cost reduction strategies for them.